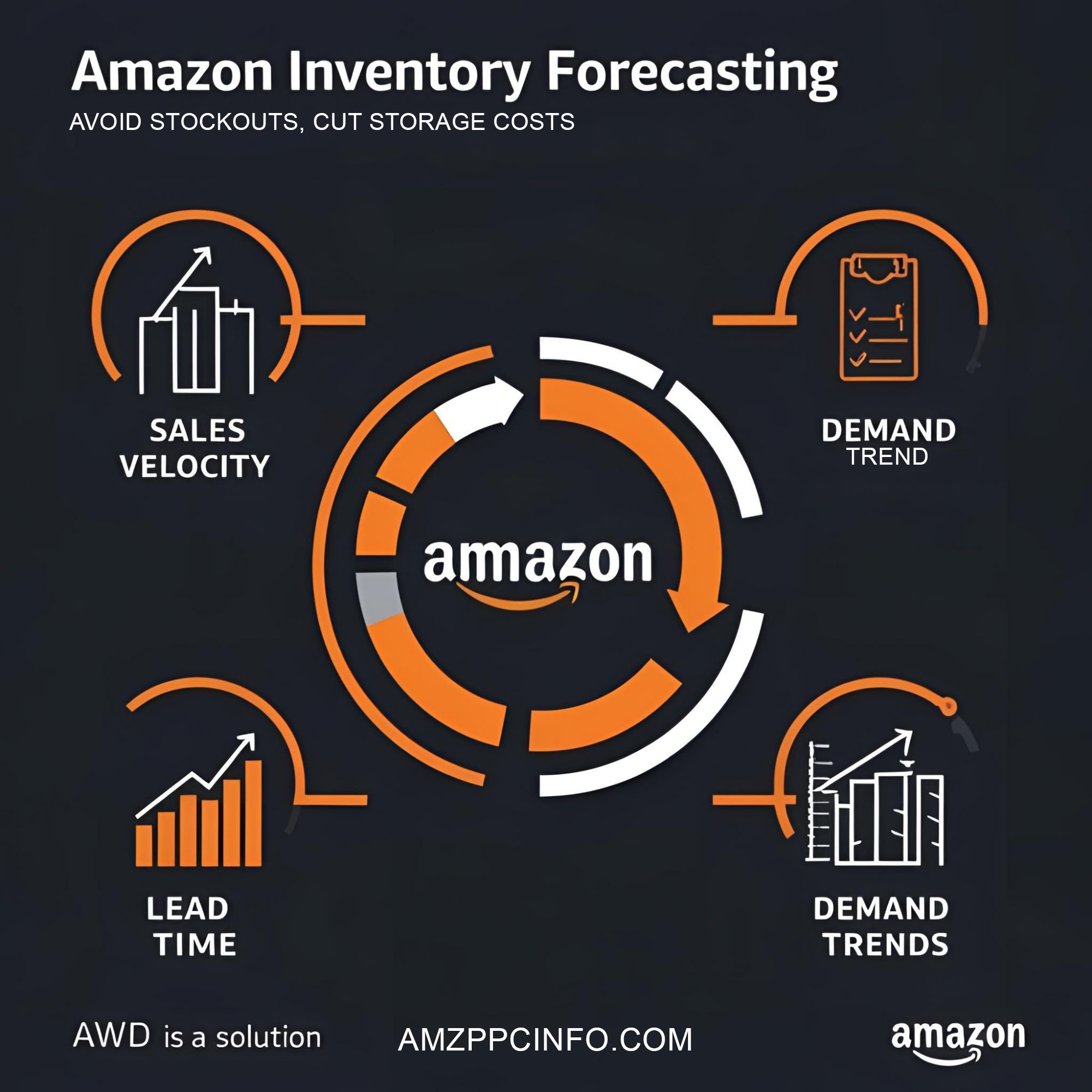

Keeping the right inventory levels is one of the most important—and most overlooked—parts of running a profitable Amazon business.

Poor forecasting can lead to two major problems:

❌ Stockouts, which result in lost sales and rankings

❌ Overstock, which triggers high Amazon storage fees and low IPI scores

Let’s break down the 3 main factors to help you forecast smarter.

📌 1. Sales Velocity

Your average daily or weekly unit sales are the foundation of your forecast. Use your historical data and real-time insights to understand how quickly your products move.

📌 2. Lead Time

Lead time includes everything from production to shipping to FBA check-in. Even minor delays can cause stockouts—especially if you don’t build buffer stock into your plan.

📌 3. Seasonality & Demand Trends

Promotions, holidays, or seasonal demand spikes must be factored in. Amazon’s demand forecasting tools or third-party tools can help you stay ahead.

💰 The Hidden Cost of Poor Forecasting

Amazon now penalizes low inventory levels through higher fees and reduced eligibility for Prime or ad placements. And if your Inventory Performance Index (IPI) drops too low, your storage limits may be restricted.

✅ Solution: Use AWD to Stay in Control

With Amazon Warehousing and Distribution (AWD), you can:

- Store bulk inventory at low cost

- Automatically replenish FBA

- Avoid emergency shipping fees and last-minute stockouts

- Maintain a high IPI score

AWD bridges the gap between long-term planning and short-term fulfillment needs—especially useful during peak seasons.

📈 Benefits of Better Inventory Forecasting:

- Reduced storage and logistics costs

- Higher product availability (no missed sales)

- Improved IPI score and FBA eligibility

- Healthier profit margins

Want help building an inventory forecast tailored to your store?

Ready to take control of your inventory? [Book a free strategy session.]